With the opportunity to generate intricate types with a smaller scale, these machines can be a testomony to how considerably CNC technology has arrive.

Easy machine Understanding allied with details-driven solutions for checking Device have on in machining processes

The way forward for CNC machining is undeniably interlaced with artificial intelligence. As AI carries on to evolve, its job in machining will increase, featuring new prospects for innovation and efficiency.

Contrary to guide lathes, a CNC milling machine operates by converting a 3D CAD product into a set of computer Guidance, which can be then used to dictate the tooling’s steps and actions automatically.

Optimizing parameters: AI adjusts machining parameters which include feed rates and spindle speeds according to product and machine abilities.

After the provision line disruption and distressing actuality of where by manufacturing shortfalls in 2020, AI is aiming to swoop in and conserve the working day.

The technical storage or entry is necessary for the reputable purpose of storing Tastes that aren't requested because of the subscriber or consumer. Stats Figures

Delving into the planet of CNC milling, one particular speedily realizes the paramount value of precision and accuracy. These two elements are the bedrock of efficient CNC operations, ensuring that the final products meets the specified requirements and high quality criteria.

There are lots of CAM software program solutions obtainable on the market, Every single with its Understand distinctive capabilities and capabilities.

Now, I know very well what you might be wondering. If AI is so terrific, why is just not everyone using it? Very well, utilizing AI in CNC machining isn't straightforward. Here are a few difficulties you might facial area:

Cost-effectiveness: AI’s predictive abilities allow for for proactive upkeep, leading to cost personal savings by making certain timely servicing.

Some manufacturers mount independent milling heads with Device transform abilities make this machining center much more efficient.

Once you've determined your use conditions, it is time to pilot and iterate. This means commencing small, screening your AI Resolution, Discovering from the results, and iterating according to Everything you've uncovered.A great way To accomplish this will be to Adhere to the lean startup methodology. This is the method of acquiring businesses and products and solutions, which aims to shorten product development cycles and rapidly uncover if a proposed organization product is practical.

Instrument and Die Generating: CNC mills are generally used in Resource and die earning because of their precision and skill to machine hard supplies precisely.

Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Batista Then & Now!

Batista Then & Now! Erika Eleniak Then & Now!

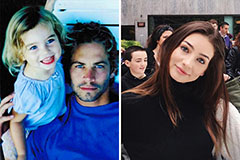

Erika Eleniak Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now! Naomi Grossman Then & Now!

Naomi Grossman Then & Now!